- tungsten, molybdenum, tantalum, niobium and rhenium,ods-copper,

cemented carbide.

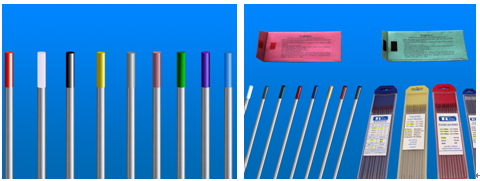

Electrodes for TIG

TIG welding electrodes - Application

TIG welding is under the environment of the inert gas such as argon. The electric arc between tungsten electrodes and parent metal make the parent metal and welding material melting together.Due to the excellent properties, tungsten is very suitable for the TIG welding electrode materials.

TIG welding electrodes - Material Property

We can improve the welding performance of tungsten electrode by adding rare earth elements such as lanthanum oxide, zirconium oxide, yttrium oxide and thorium oxide, etc.TIG welding electrodes - Features

-- Suitable for almost all industrial metals and alloys- Highly reliable welding quality

- Good welding shape, no need to remove the slag

- No splash

- Less smoke

- Suitable for different thickness of plate

TIG welding electrodes - Classification

DC TIG welding uses DC power source as the welding power source. Tungsten electrode is used as negative pole, parent metal as positive pole. This method is widely used in stainless steel, titanium, copper and copper alloy welding.AC TIG welding uses AC power source for welding power source. During the process, negative pole and positive pole keep on changing all the time .When the positive pole was overheated, the oxide layer on the surface of the parent metal would be removed. Base on the cleaning effect, AC TIG welding is widely used in the welding of aluminum, magnesium, and etc.

TIG welding electrodes - Specification

Size: Diameter 0.5-25mmLength: 150mm, 175mm, 178mm and any other length at customer's request. More info at Products page.

Select the electrode diameter according to the welding current:

|

Electrode Diameter |

DC(A) |

AC(A) |

|||

|

in |

mm |

Straight Polarity(-) |

Reverse Polarity(+) |

Unbalanced Waves |

Balanced Waves |

|

0.04" |

1.0 |

15-80 |

|

10-80 |

20-60 |

|

1/16" |

1.6 |

60-150 |

10-18 |

50-120 |

40-100 |

|

0.079" |

2.0 |

100-200 |

12-20 |

70-160 |

60-130 |

|

3/32" |

2.4 |

150-250 |

15-25 |

80-200 |

80-150 |

|

1/8" |

3.2 |

220-350 |

20-35 |

150-270 |

120-200 |

|

5/32" |

4.0 |

350-500 |

35-50 |

220-350 |

170-260 |

|

3/16" |

4.8 |

420-650 |

45-65 |

240-420 |

220-340 |

|

1/4" |

6.4 |

600-900 |

65-100 |

360-560 |

250-450 |