- tungsten, molybdenum, tantalum, niobium and rhenium,ods-copper,

cemented carbide.

Components for Nuclear Power & Energy

Application:

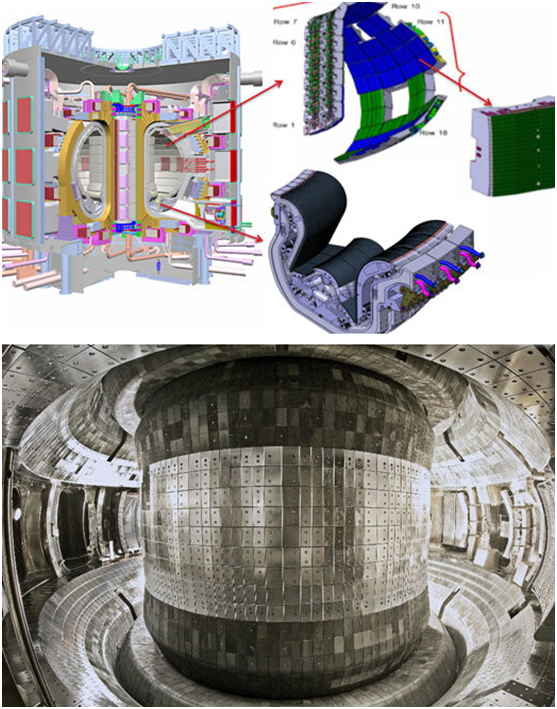

The nuclear fusion research is a major international cooperation program implemented by the world's scientific community to address energy problems to be faced by humans in the future. Different from non-renewable energy resources and the conventional clean energy, fusion energy has the advantages of unlimited resources, no pollution to the environment, no production of high-level radioactive nuclear waste, etc., will be one of the dominant forms of energy in the future, and is one of the important ways currently recognized to be able to ultimately solve energy problems and environmental issues so as to promote the sustainable development of human society.International Thermonuclear Experimental Reactor is a superconducting tokamak that enables large-scale nuclear fusion reactions. The plasma torus is in the ring-shape sheath of the shield blanket. The shield blanket will absorb 500,000 kilowatts of thermal power and all neutrons generated by the nuclear fusion reaction. Therefore, thermostable materials are needed to serve as the plasma-facing first-wall materials. Tungsten-copper composite parts, TZM and molybdenum-copper materials produced by XYXC can be used as the first-wall materials.

Material Introduction:

Plasma-facing material is one of the most critical materials in the fusion reactor. The main requirements of the material are with low sputtering rate, high thermal shock resistance, high heat load capacity, low tritium retention, low activity radioactive and low decay heat. Through years of research, engineers found that tungsten metal material is the best choice.Product Specification:

Our tungsten products meet all the requirements of ITER as follows:Table 1 – Chemical composition of W plates

|

Element |

Composition max, wt. % |

Permissible variation in Check analysis, wt. % |

|

C |

0.01 |

±0.002 |

|

O |

0.01 |

+10% 相对 |

|

N |

0.01 |

+0.0005 |

|

Fe |

0.01 |

+0.001 |

|

Ni |

0.01 |

+0.001 |

|

Si |

0.01 |

+0.001 |

Table 2 – Grain size requirements of W plate

|

Thickness[mm] |

Grain size [ASTM Standard] |

|

|

>10 |

3 or finer |

|

|

Thickness[mm] |

Hardness HV30 |

|

|

>10 |

≥410 |

|